High-volume industrial wood waste & costly annual disposal fees.

A dedicated pallet repair-and-return facility, less than 10 miles from their warehouse.

Estimated annual cost savings of $2 million, with 8,000 repurposed pallets saved from landfills every month.

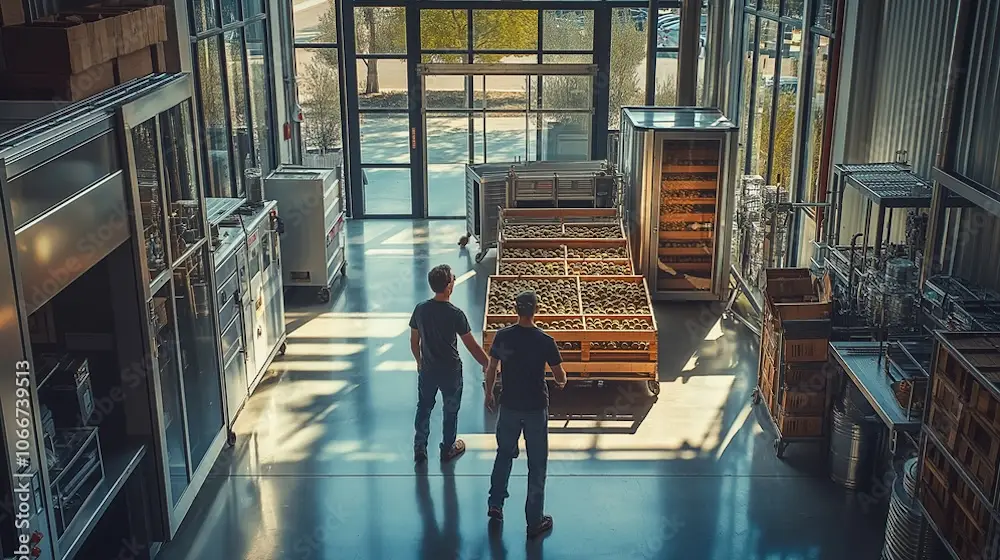

A global leader in the design and manufacture of kitchen, bath, and plumbing products came to us through a client referral. One of their factories faced a growing problem: it was spending over $60,000 a month on wood pallet disposal, and generating enough waste to fill 120 industrial-size dumpsters every year.

Not only were they discarding tens of thousands of wood pallets annually, but they were paying full price for replacement pallets with each new order. In short, they faced two pressing challenges: inefficient, mounting disposal fees and unsustainable landfill waste at a high environmental cost – contrary to the company’s long-term net zero goal.

We quickly recognized that this customer needed a large-scale, sustainable system for repurposing and recycling their existing pallet inventory rather than a quote for competitively-priced new wood pallets that would not address their underlying cost-saving and ESG requirements.

A proactive, closed-loop approach was required, so we proposed a custom-built, local solution that could be completed in a timeframe that matched their needs.

Within just a few months, we successfully:

Our specialists work with each of our clients to create Integrated Plans that allow them to customize and select the products and services that work best for them across multiple locations.

The results were immediate and impactful. Each month, our custom-built facility repairs and repurposes approximately 7,800 pallets — totaling around 93,600 pallets annually— saving countless pallets from landfill and significantly reducing our customer’s carbon footprint, in line with their commitment to environmental sustainability.

They accomplished this while boosting their bottom line: by transitioning from a disposal-based pallet management system to a sustainable, local refurbishment model, our customer realized estimated annual savings exceeding $2 million (based on combined disposal fees and new pallet purchasing costs).

We believe we were able to make the most of this circular logistics opportunity because we are committed to being a full-service solution provider, not just a pallet supplier.

Our expansive network of repair and production facilities nationwide allows us to track, recover, refurbish, and promptly return pallets to customers at significantly reduced costs, no matter their location – even if that means building an entirely new facility to serve a customer’s needs.

No matter what roadblock you may be facing, we are confident that, together, we can discover a pathway that serves your unique growth and sustainability aspirations. Contact us today to start the conversation.

We understand that time is one of your most valuable assets; that’s why we work hard to provide every one of our clients with a systems-based approach to improving quality and reducing costs while increasing efficiency. Whether you are looking for a single product or need a more comprehensive solution, our business is to support and serve the needs of your business.

We work with each of our clients to:

We look forward to talking with you to learn how our team can serve your business.